Questions? We are all ears!, Drop us an email at info@insuzo.com or call us on +91 8920884830

Shop By Industry

Visit Store

© 2023.Insuzo. All Rights Reserved.

Electrical and Electronic

Environmental

General Laboratory | Analytical

Imaging Instruments

Mechanical and Quality Control

Time, Speed and Dimension

Tools

Calibrators

Shop By Industry

Item(s) Added To Your Bag

Top Industry : How to be Number one in the industry

Top Industry : How to be Number one in the industry

25 Jan , 2024

Pressure Pumps are mechanical devices that pump fluids by the use of pressure. Pumps are a critical component of water distribution systems, typically used to pump water from the ground. They are also vital components of various industries, plantation, agriculture and manufacturing.

Pressure Pumps differ in their use, construction, operations and most importantly, their performance. They are a viable alternative to wells and can be used in locations where there is no natural groundwater. The many types of Pressure Pumps and their applications are discussed in this blog.

On the basis of operations, Pressure Pumps can be broadly divided into two types-

Positive Displacement Pumps: Positive Displacement Pumps work by trapping a fixed amount of water and then forcing it out under pressure. These pumps are often used in applications where a constant flow rate is required, such as in firefighting or industrial process control.

Reciprocating Pumps: Reciprocating Pumps use a piston to draw water into the pump chamber and then force it out under pressure. These pumps are typically used for high-pressure applications, such as in hydraulic systems.

There are many different types of Pressure Pumps, each with its own specific uses. Here, we’ll take a look at some of the most common types of Pressure Pumps and their uses.

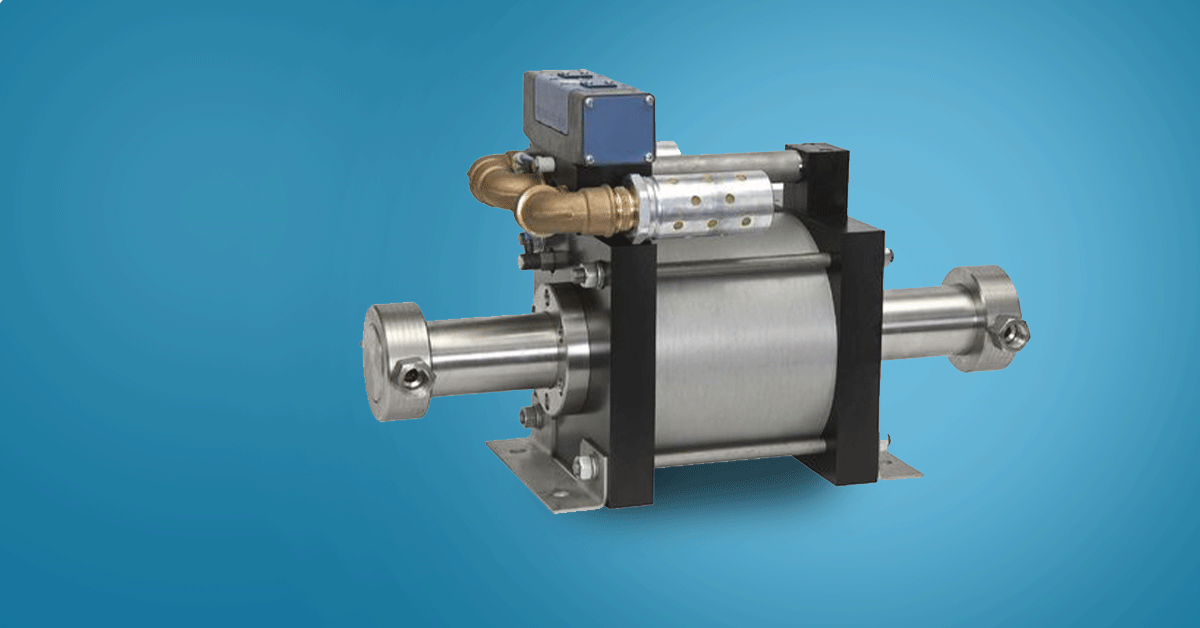

A Pneumatic Pump is a machine that uses compressed air to create a vacuum. This makes the pressure in the pump lower than the pressure in the pipe being pumped. The air is then used to create a vacuum, which can be used for various purposes, such as removing water from a boat or pumping water out of a swimming pool.

Pneumatic Pumps are used for many different applications. They have a variety of uses, from pumping water to running paint guns and more. They are used in many industries such as automotive, food processing, medical, and more.

Pneumatic Pumps can be broadly classified into two categories on the basis of operation:

Types of Pneumatic Pumps-

Rotary Vane Pump: These are often found in automotive factories where they transfer gas from one container to another or from a container to a storage tank.

Diaphragm Pump: It has two parts- an airtight chamber and an elastic membrane with valves on each end. This type of pump can be found in food processing plants where it transfers liquids between containers or tanks by sucking them up through the valve.

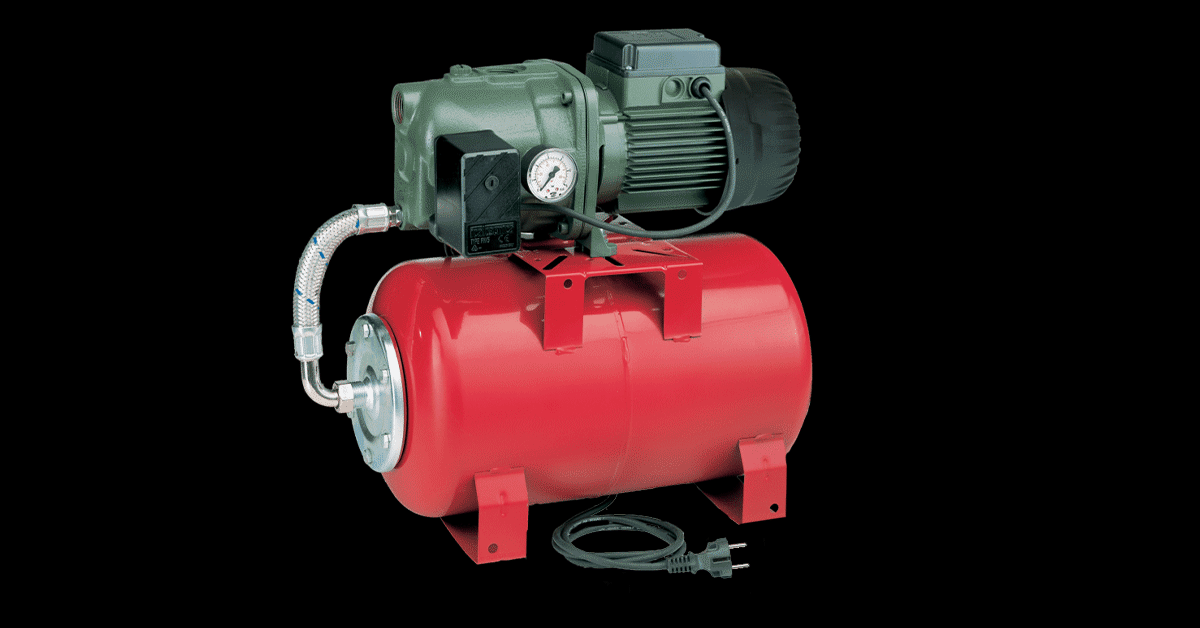

Booster Pumps are used to increase water pressure in the pipes. They are usually used in areas where the water pressure is low or when there is a need for more water pressure.

An oil or gas well requires a considerable amount of water to produce hydrocarbons at the desired rate. The amount of water required is determined by a number of factors such as the depth below ground level, temperature, pressure in the wellbore, etc. The production rates can be increased by using Booster Pumps. These pumps help extract water from deeper levels which increases the production rate at shallow levels.

Booster Pumps can be powered by electricity or by gas. The Electric Booster Pump is usually installed on top of the well and connected to an electric source through a long wire. A Gas-Powered Booster Pump is usually mounted on a concrete base and connected to a natural gas supply line.

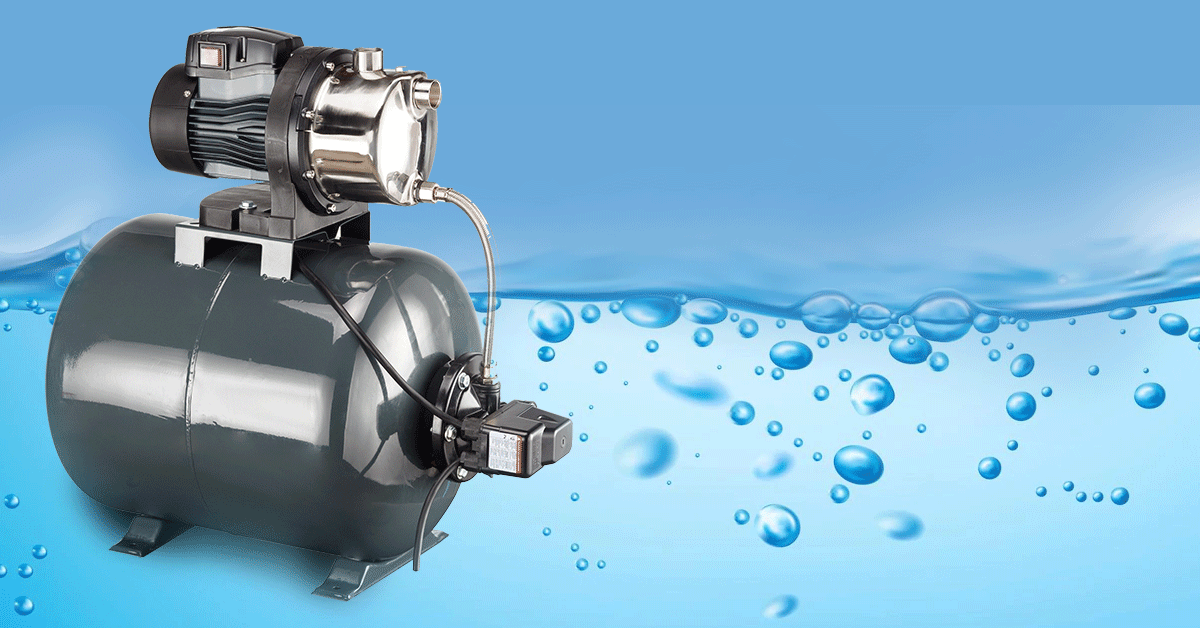

Centrifugal Pumps work by spinning a rotor connected to an impeller that draws the liquid into it. The liquid is then pushed out through the pump’s discharge nozzle at high pressure. They are used for lifting water and other fluids from lower to higher elevations.

Centrifugal Pumps are one of the most commonly used types of pumps in industries such as oil, gas and water. They are also used to provide a constant supply of water for domestic and commercial uses.

Centrifugal pumps need to be installed in a way that the discharge pipe is at least one meter below the surface of the water in order to avoid any air bubbles. They should be installed with an overflow pipe so that if there is any excess pressure, it can be released without damaging the pump.

Any Query? Reach Us

Reach Us

The Office Address

305 P.P. Trade Center, Netaji Subash Place, Pitampura, Delhi - 110034

For Support

8920884830

Send Us Email

info@insuzo.com

Copyright © 2024. Insuzo

All Rights Reserved.

.png)